Turning

We manufacture simple and complex parts, as well as turned and milled parts, which range from single components to small batches, on our state-of-the-art CNC lathes. If you provide us with a 3D model, the CNC programs are created via a CAM system.

Electrical discharge machining

We can produce complex, exceptionally precise components with excellent surface finishes on our modern wire EDM machine. A rotational axis can also be applied to this machine so that components can be made by making one single setting and therefore achieving a high degree of precision. The programs are created with a CAM system.

Grinding

We can also produce highly precise components on our manual surface- and cylindrical grinding machines. We can carry out surface grinding up to lengths of 1200 mm and cylindrical grinding up to an exterior diameter of 300 mm and an interior diameter of up to 140 mm.

Milling

We manufacture simple and complex parts, which range from single components to small batches, on our modern CNC lathes. If you provide us with a 3D model, the CNC programs are created via a CAM system.

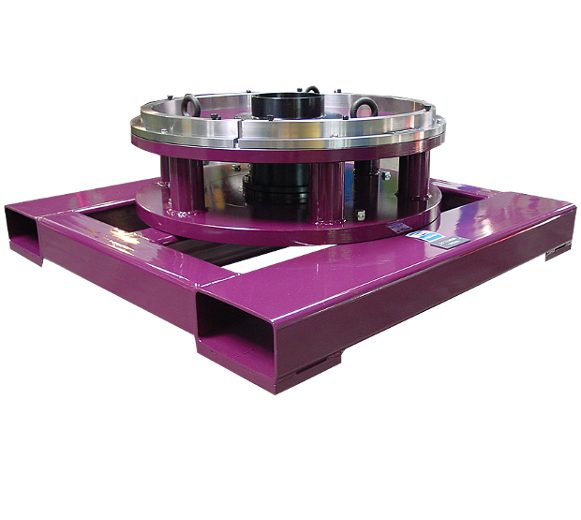

Contract manufacturing

We can manufacture highly accurate turned, milled, ground or sheet-metal parts, welded items, entire devices, or customised machines in house. Our exceptional degree of vertical integration, highly skilled personnel and our wide range of machinery allow us to carry out most of the jobs on site. As a result we save valuable time because we don’t have to subcontract and can therefore cut the lead time for complex components drastically.

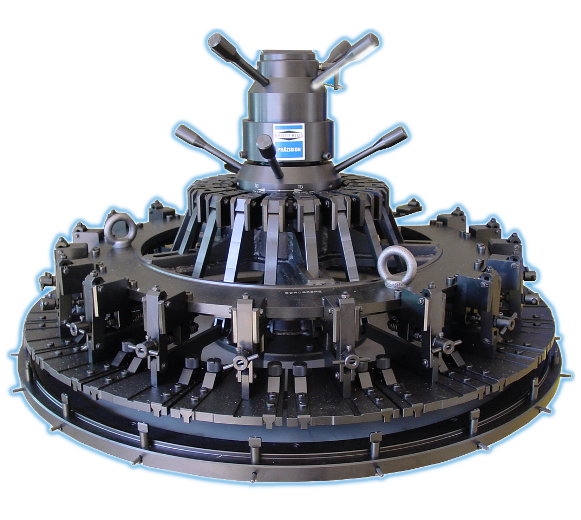

Welding

We’ve been a DIN-certified specialist welding company (DIN 11800-7 class D - advanced certificate) since 2004. In 2013 we extended our certification to DIN 18800-7 class E and introduced qualification for EN-1090-1 EXC 3. We provide in-house manufacture of welded assemblies and complex lifting gear to move aircraft engines for example. Our portfolio also covers containers, which are among other things used to transport engine modules by air.